Ever heard of Impedance? No! Here’s all you need to know about Impedance Control PC

What is meant by Impedance?

Impedance is used to calculate the opposition of an electrical circuit when an alternate current is given to it. Impedance is formed when capacitance and induction of an electrical circuit are combined at high frequencies. The measuring unit of impedance is Ohms same as resistance. But always remember, never to confuse impedance with resistance as resistance is the characteristic of direct current. When the signal passes from a conductor with a required impedance to another of an identical impedance, the transmission becomes optimum. On the contrary, if both of the impedances are not similar then reflections and attenuations can occur causing deteriorated signals. Impedances are based on frequency.

How is impedance set on?

Mostly, the trace impedance occurs between 25 to 125 Ohms. Some factors are affecting the impedance. They are:

- Resistance

- Inductance

- Capacitance

- Frequency

- Copper width and thickness

- Signals passing through different vias

- Solder resist presence

- Reference copper plain distance

Therefore, all the board designers must be sure that in the case of high-frequency signals, their choices of stack up and traces must make it attainable to get a targeted impedance value, with an unquestionable tolerance. Nowadays, superior advanced electronics CAD design equipment and tools can measure it automatically.

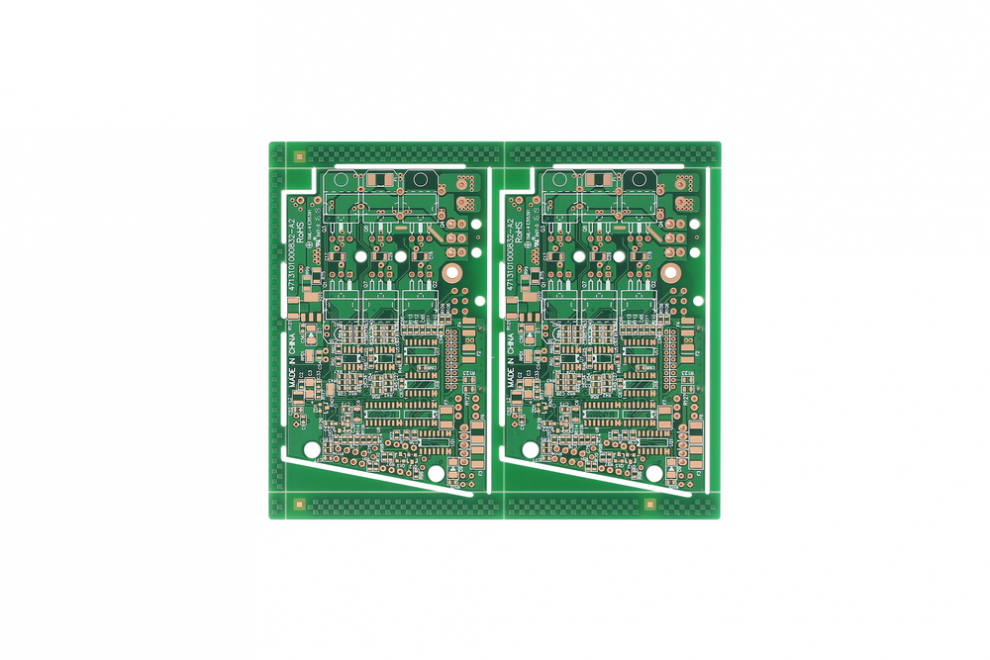

What is meant by impedance control PCB?

Impedance control involves calculating the impedance of attainable traces at the time when PCB is produced and making sure they are working within their limits highlighted by the designer. Even though it is not cheap but instead expensive, a fact is that this technique has become extensive after the change in the century due to the continuous increase of frequencies of electronic components and equipment. It promotes the following products:

- Digital and analog telecommunications.

- Signal processing of videos.

- Digital cameras

- Televisions

- GPS

- Video games

- Computers, mobiles, and tablets

- Motor control modules

What has controlled impedance?

Controlled impedance is the twinning and matching of trace dimensions and locations with substrate material properties to make sure that the impedance of a trace signal is within an attainable percentage of a required specific value.

Why do we need to control impedance on PCB?

At high frequencies, PCB traces do not act like simple links and connections. Controlled impedances help us to make sure that signals are not being undegraded and underestimated as they route around a PCB. This is known as Impedance Control PCB.

Why does controlled impedance bother?

Each day, PCB designs are becoming smaller and faster. In simple words, this means they are becoming more and more complicated day by day.it is now becoming important for us to understand our traces and critical nets as well as impedances, also how the board affects the performance of the signal. The era of simple connection traces and conductors is already finished. Day by day, the circuit speeds are increasing and the signals in the GHz range are becoming common. So, the controlled impedance of traces is really important for signal integrity and the circuit board performances.

Follow Techrado for more!